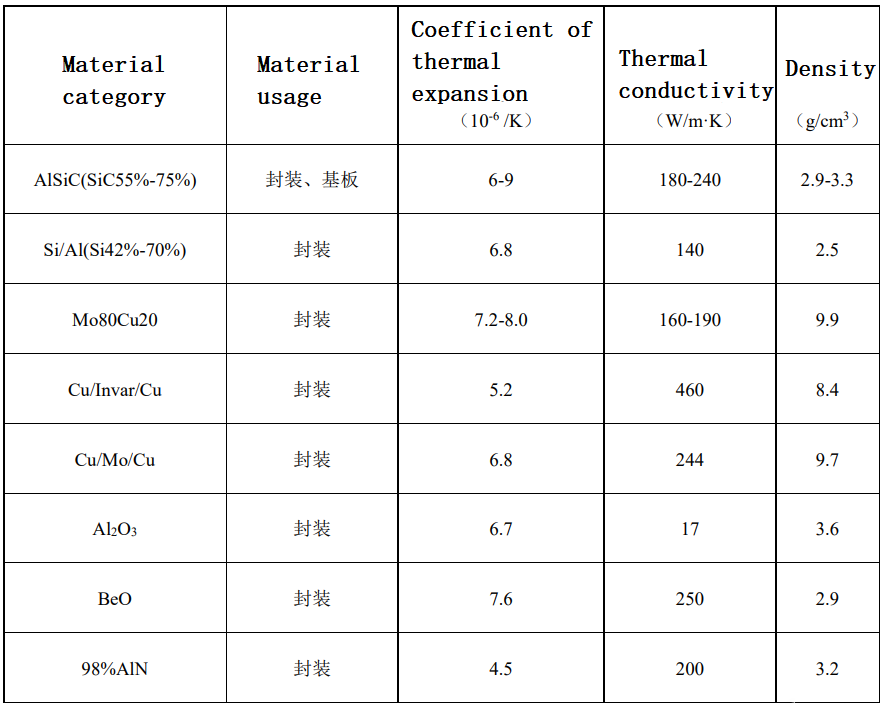

The expansion coefficient of aluminum based silicon carbide can be adjusted by the volume fraction of SiC and the amount of adhesive added, so as to achieve thermal matching with GaAs chips, alumina, aluminum nitride and other substrates; At the same time, a member having a complex shape can be relatively formed.

In terms of IGBT modules, IGBT modules are composed of seven layers, which can be roughly divided into three parts: chip, DBC and substrate. These three parts are matched and stacked to form a complete IGBT module. Among them, the DBC part needs a substrate, and the bottom layer also has a substrate as a bottom plate. Most of the bottom plate substrates are copper substrates.

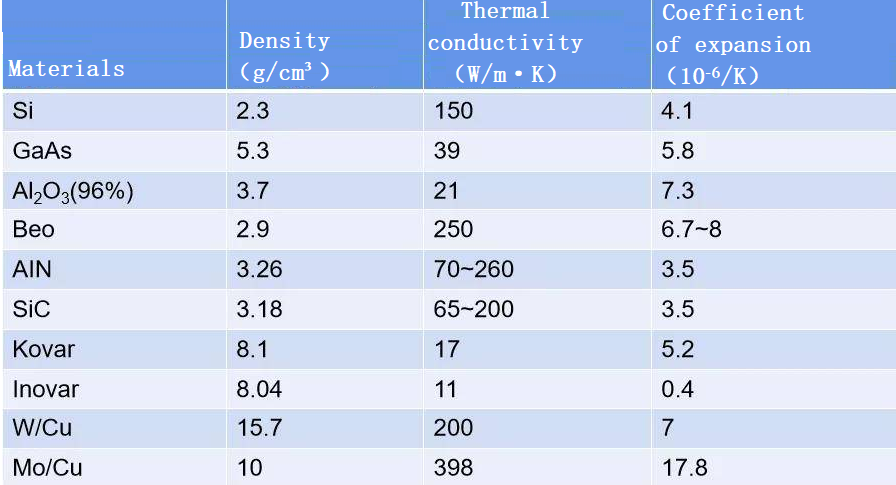

List of common heat dissipation materials and key parameters on the market

The advantage of the copper substrate is that it has a thermal conductivity of nearly 400, but the disadvantage is that his coefficient of thermal expansion is about three times that of the chip, and the difference is that in the low-power module package, it can be solved by ceramic copper clad laminate or multilayer ceramic copper clad laminate. However, if the high-power module uses a copper substrate to carry the chip substrate and connects the radiator below, the welded copper substrate cannot withstand 1000 thermal cycles, and the welded outer edge will be delaminatedIn this case, if it is used in a vibration environment for a long time, such as rail locomotives, electric vehicles, aircraft, etc., its reliability will be greatly reduced. In addition, the mismatched coefficient of thermal expansion between copper and ceramic materials will also lead to the generation of thermal stress between IGBT module materials, generating mechanical strain in the solder, and serious cases will lead to cracking of the solder, increasing the thermal resistance between the chip and the substrate, thus causing serious quality problems. For example, the difference in thermal expansion coefficients between copper (17×10-6/°C) and aluminum nitride DBC (7×10-6/°C) is prone to cracking between copper substrates and aluminum nitride DBC after multiple thermal cycles. The coefficient of thermal expansion of aluminum-based silicon carbide with a volume fraction of more than 55 is very similar to that of DBC aluminum nitride. Aluminum-based silicon carbide or will replace the copper substrate in the IGBT module, if the surface flatness of the material after processing reaches the standard, it can even achieve the effect of the chip directly encapsulated on the aluminum-based silicon carbide substrate.

In other packaging fields, such as new energy vehicle related chip packaging, communication cavity, etc. The basic applications are aluminum-based silicon carbide with a volume fraction of 55-70. Aluminum-based silicon carbide with high volume fractions is typically prepared using only two preparation methods, namely pressure-free permeation and powder metallurgy.

Comparison chart of processing technology

The advantages of the pressureless osmosis process and the powder metallurgy process can be seen in the chart, both of which can reach the size of the nano to micron level and the uniform interface of the reinforcement is well combined, but the porosity of powder metallurgy is much smaller than that of the pressureless permeation (the volume of the pore inside the material accounts for the percentage of the total volume of the material) And the process maturity is also higher. The preparation process of high-volume fractional aluminum-based silicon carbide produced by us is the powder metallurgy process, and we can also adjust the proportion of powder according to customer needs to achieve certain performance improvements. Other special requirements: such as functional requirements (electromagnetic / RF / radiation shielding, conductive / insulation, etc.) can be solved by coating of different materials, please contact our customer service for details.

Encapsulation material performance chart

Pictures of some of the substrates produced by Hanyin Optoelectronics

Copyright © 2022 -

Henan Hanyin Optoelectronics Technology Co., Ltd.

备案号:

豫ICP备2022007983号-1 网站地图

腾云建站仅向商家提供技术服务