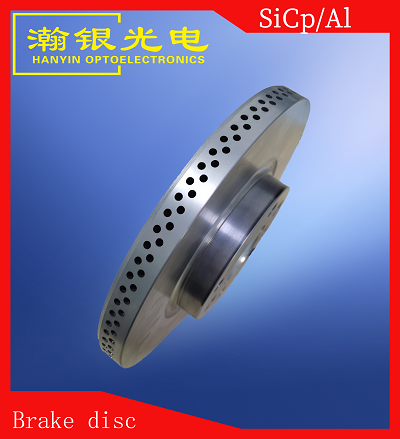

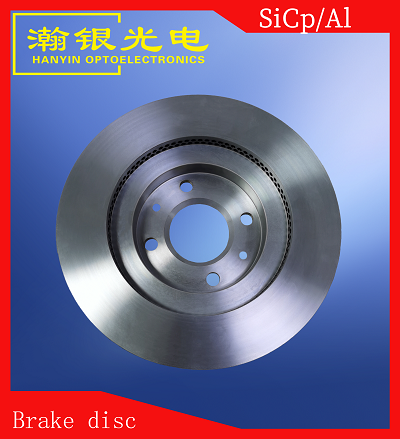

High speed train brake disc and automobile brake disc are one of the most critical components in the brake device. With the acceleration of the train and the bad operating conditions under braking conditions, the huge braking thermal load and thermal shock will produce a large temperature gradient, resulting in the formation of great thermal stress in the brake disc. Therefore, it is required that the brake disc material not only has stable and uniform friction performance and high wear resistance, but also has high thermal fatigue performance and thermal conductivity, low elastic modulus and thermal expansion coefficient, so that the brake heat can escape quickly, so as to reduce the high thermal stress formed by the rapid cooling and heating of the brake disc friction surface.

1、 Brake disc material of traditional high-speed rail motor car

Cast iron material: generally used for rail vehicles with low speed. At the same time, different cast iron materials will be selected due to different speeds, including ordinary cast iron, gray cast iron, nodular cast iron, low alloy cast iron, etc. Brake discs made of cast iron can only be used for rail trains with speed below 200 per hour.

Alloy steel materials: alloy steel materials can meet the requirements of 350 km/h for brake discs, including cast steel materials, forged steel materials, etc., which have been widely used in high-speed EMUs.

2、 Comparison between aluminum based silicon carbide material and traditional brake disc material

The density of traditional steel cast brake discs is high, which is not conducive to lightweight; At the same time, due to the low thermal conductivity of cast iron, the heat generated in the braking process is difficult to dissipate in time, which leads to high temperature gradient on its surface and inside, which is easy to produce hot cracks, thus reducing the safety.

In view of the disadvantages of traditional materials, our company, through independent research and development, has broken through the powder metallurgy large-size ingot casting technology. While meeting the super size of high-speed railway brake discs, our company has the advantages of light weight, high thermal conductivity, high specific heat, corrosion resistance, wear resistance and high temperature resistance. Compared with the brake discs cast by Tonggang, our company has reduced the weight by 50-60% and increased the thermal conductivity by more than 2 times.

Comparison between aluminum based silicon carbide material and traditional brake disc material

Performance index | Traditional materials | Aluminum based silicon carbide |

Density(g/cm3) | 7.2-7.8 | 2.8-2.9 |

Elastic modulus(GPa) | 126-140 | 160-195 |

Thermal conductivity(W/m·K) | 35-90 | 190-200 |

3、 Overview of current application

At present, cast iron, cast steel or forged steel brake discs are used on the imported EMUs CRH1/CRH2/CRH3/CRH5 (200-300km/h); On CRH380A/CRH380B (350 km/h), the brake disc made of cast steel is used.

CRRC Zhuzhou Locomotive Co., Ltd., CRRC Sifang Research Institute and CRRC Qishuyan Research Institute have successfully applied aluminum matrix composite materials to double layer EMUs, train brake discs and other fields, with obvious weight reduction effect, which can improve the friction performance while ensuring the strength and toughness of materials, reduce operating energy consumption and improve vehicle dynamic performance.

Copyright © 2022 -

Henan Hanyin Optoelectronics Technology Co., Ltd.

备案号:

豫ICP备2022007983号-1 网站地图

腾云建站仅向商家提供技术服务