Henan Hanyin Optoelectronic Technology Co., Ltd. has built two production lines of "powder metallurgy process" and "Infiltration casting process", breaking through the high-performance, macro quantitative ingot preparation technology, able to mass-produce large-scale (single ingot weight: up to 12 tons),Low, medium and high volume ceramic particles reinforced aluminum matrix composite ingot.is committed to becoming the world's largest ceramic particle reinforced aluminum matrix composite material research and development and industrialization base, establish a domestic aluminum matrix composite material "high performance, large specification" image, at the same time, To achieve collaborative development between material research , preparation and processing and system users,faster, better and better service to domestic and foreign high-precision equipment manufacturers.

Table 1 Performance parameters of other traditional materials

Material | Density g/cm3 | Elastic modulus GPa | Strength MPa | Specific stiffness E/p | Coefficient of expansion 10-6/K | Thermal conductivity W/m·K |

Tradition material | Titanium alloy | 4.4 | 110 | --- | 25 | 9 | 8 |

Aluminum alloy | 2.7 | 70 | --- | 25.9 | 23.1 | 159 |

Beryllium metal | 1.85 | 303 | --- | 163.8 | 11.4 | 216 |

ULE glass | 2.2 | 67 | --- | 30.5 | 0.03 | 1.3 |

SiC | 3.1 | 391 | --- | 126.1 | 4.3 | 170 |

Silicon carbide aluminum matrix composites have excellent performance and have many outstanding advantages: low density, high specific stiffness, low coefficient of thermal expansion, high thermal conductivity, etc., which are very suitable for high stability optical machine systems. For example: (1) high structural stability (static stiffness, dynamic stiffness): the elastic modulus is 2 times that of titanium alloy, 3 times that of aluminum alloy, and the specific stiffness is 3 times that of aluminum alloy and titanium alloy; (2) high thermal control stability: the coefficient of thermal expansion can be 20% lower than that of titanium alloy, and the thermal conductivity is 30 times that of titanium alloy. Therefore, silicon carbide aluminum matrix composites have become an ideal material to replace other alloys.

Table 2 Performance parameters of aluminum matrix composites and other composite materials

Material | Density g/cm3 | Elastic modulus GPa | Strength MPa | Specific stiffness E/p | Coefficient of expansion 10-6/K | Thermal conductivity W/m·K |

SiC/Al

| 15vol%SiC/Al | 2.82 | 100±5 | 560 | 35.5 | 17.0±1 | 150±5 |

20vol%SiC/Al | 2.85 | 110±5 | 580 | 38.6 | 16.0±1 | 160±5 |

25vol%SiC/Al | 2.86 | 115±5 | 600 | 40.2 | 14.3±1 | 170±5 |

30vol%SiC/Al | 2.89 | 125±5 | 560 | 43.3 | 13.0±1 | 175±5 |

45vol%SiC/Al | 2.92 | 160±5 | 500 | 54.9 | 11.5±1 | 190±5 |

55vol%SiC/Al | 2.95 | 195±5 | 450 | 66.1 | 9.5±1 | 200±5 |

60vol%SiC/Al | 2.98 | 200±5 | 420 | 67.1 | 8.3±1 | 205±5 |

65vol%SiC/Al | 3.01 | 215±5 | 400 | 71.4 | 7.5±1 | 210±10 |

70vol%SiC/Al | 3.02 | 220±5 | 380 | 72.8 | 7.0±1 | 215±10 |

Si/Al | 35vol%Si/Al | 2.56 | 95 | 350 | 37.1 | 13.5±1 | 150±5 |

42vol%Si/Al | 2.54 | 103 | 350 | 40.6 | 13.0±1 | 145±5 |

50vol%Si/Al | 2.51 | 120 | 320 | 47.8 | 12.0±1 | 130±5 |

60vol%Si/Al | 2.47 | 129 | 310 | 52.2 | 9.5±1 | 135±5 |

B4C/Al | 20vol%B4C/Al | 2.69 | 105±5 | 529 | 39 | 16. 0±1 | --- |

25vol%B4C/Al | 2.68 | 110±5 | 580 | 41 | 14.5±1 | --- |

30vol%B4C/Al | 2.67 | 120±5 | 550 | 44.9 | 13.5±1 | --- |

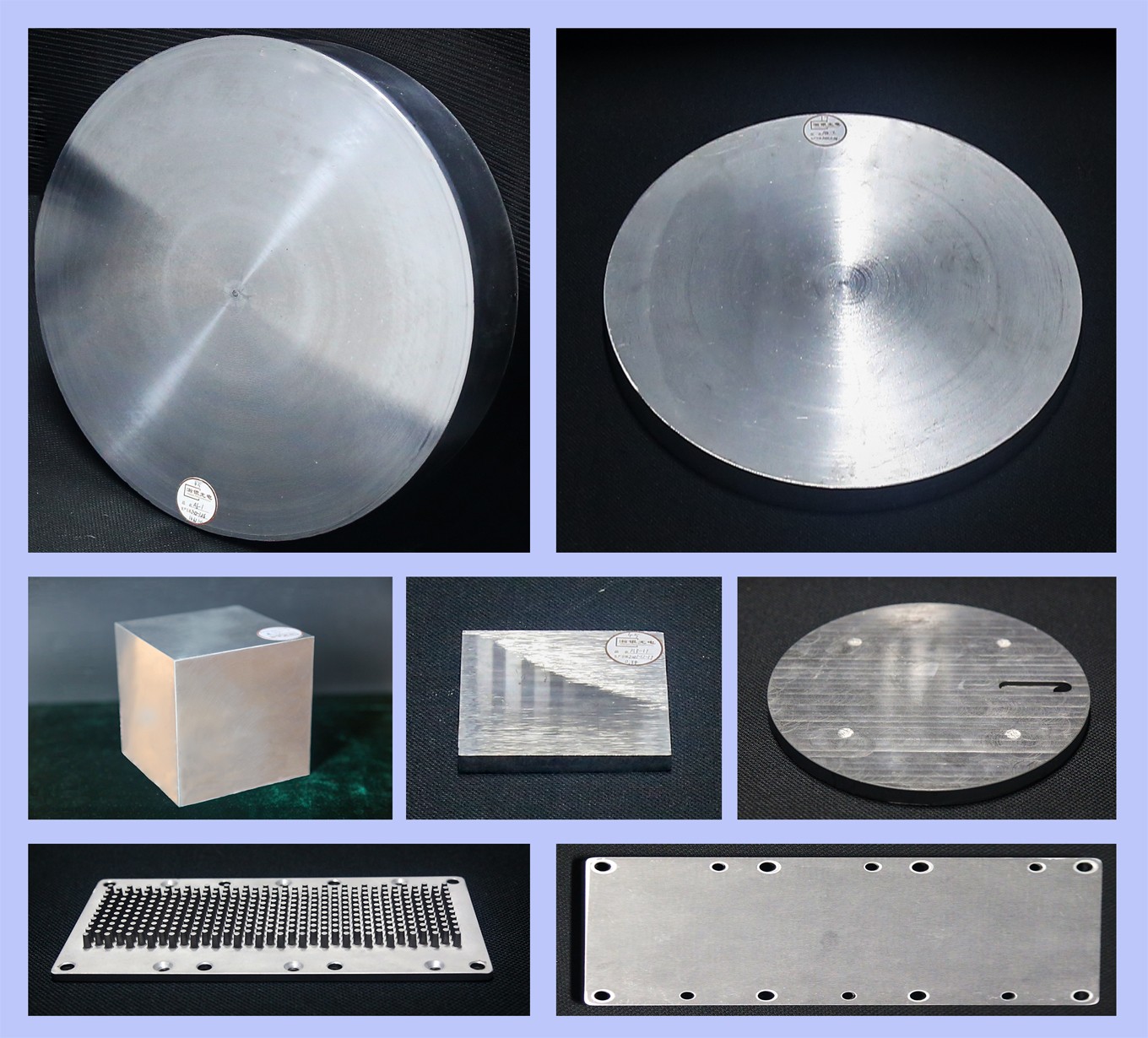

Silicon carbide aluminum matrix composite billet ingots and derivatives thereof

Copyright © 2022 -

Henan Hanyin Optoelectronics Technology Co., Ltd.

备案号:

豫ICP备2022007983号-1 网站地图

腾云建站仅向商家提供技术服务